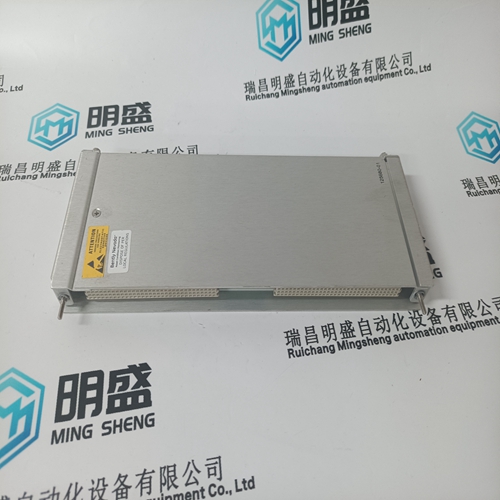

Home > Product > PLC programmable module > BENTLY 125680-01 Monitor module

BENTLY 125680-01 Monitor module

- Product ID: 125680-01

- Brand: BENTLY

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:BENTLY125680-01Monitor module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

BENTLY 125680-01 Monitor module

The MCSP should maintain expertise in evaluation and should have a systematic process for ensuring that strengths and opportunities for improvement are recorded and shared among the staff. The MCSP should have processes to manage improvements such as: knowledge management; knowledge database; technology and methodology improvements; case studies; training, briefing; internal communication. 7.5.3 Administrative matters The MCSP should have effective processes to ensure that all administrative matters are dealt with in a timely and efficient manner. These processes can include: indexing, filing, archiving; backing-up data and records; return of client property, equipment and facilities (e.g. files, records, data, security passes); release/recruitment of subcontractors and internal resources; completion of internal quality assurance procedures.

The MCSP should ensure that any obligations regarding communication about the assignment are fulfilled

(e.g. confidentiality agreements, preparation of case studies, articles, requests for references, etc.).

The MCSP should ensure that the client is debriefed at the end of the assignment.

7.5.5 Outstanding minor issues

The MCSP should have a process, agreed with the client, for dealing with any outstanding minor issues after

the completion of the assignment, so that closure can be achieved.

Associated Publications

The following publications contain additional product or installation information on Load Sharing and Speed Controls, and related components. These can be ordered from any Woodward office. Manuals can be downloaded with the following link: www.woodward.com/publications. Manual 02877, 723PLUS Digital Control Manual 25070, Electronic Governor Installation Guide Manual 26260, Governing Fundamentals and Power Management Manual 82715, Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules Product Specification 03202, Woodward Watch Window Standard Application Note 83402, PID Control

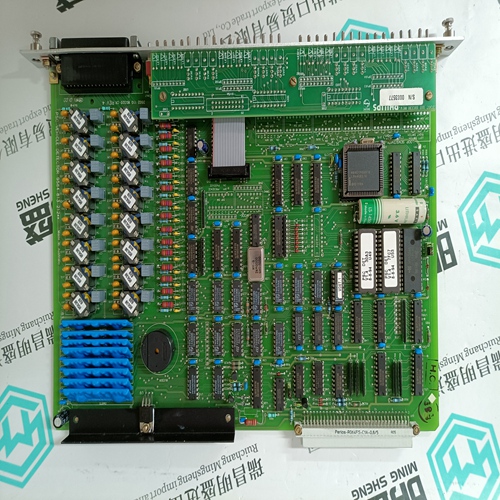

Follow these precautions when working with or near the control. 1. Avoid the build-up of static electricity on your body by not wearing clothing made of synthetic materials. Wear cotton or cotton-blend materials as much as possible because these do not store static electric charges as much as synthetics. 2. Do not remove the printed circuit board (PCB) from the control cabinet unless absolutely necessary. If you must remove the PCB from the control cabinet, follow these precautions: Do not touch any part of the PCB except the edges. Do not touch the electrical conductors, the connectors, or the components with conductive devices or with your hands. When replacing a PCB, keep the new PCB in the plastic antistatic protective bag it comes in until you are ready to install it. Immediately after removing the old PCB from the control cabinet, place it in the antistatic protective bag.

Speed Sensor Inputs

The following analog input signals have been defined for this control: Engine A Speed-Sensor Input #1 Engine B Speed-Sensor Input #2 These speed sensor inputs can be either passive (MPU) or active (PROXIMITY); The respective jumpers on the 723+ must be set accordingly (see manual 02877). Using the CONFIGURATION menu, the number of teeth for these inputs can be adjusted. Analog Inputs The following analog input signals have been defined for this control: Engine A Speed-Reference Input Engine A Load Input Engine B Speed-Reference Input Engine B Load Input Using the CONFIGURATION menu, these inputs can be enabled and assigned to any of the 4 analog inputs available on the 723PLUS. Engine A/B Speed-Reference Input This input is the nominal Speed-Reference for engine A/B. The Speed Reference Input for both engines can be assigned to the same analog input channel. Engine A/B Load Input This input is the load input for engine A/B. This could be based on a real kW measurement, torque measurement, or fuel rack position.