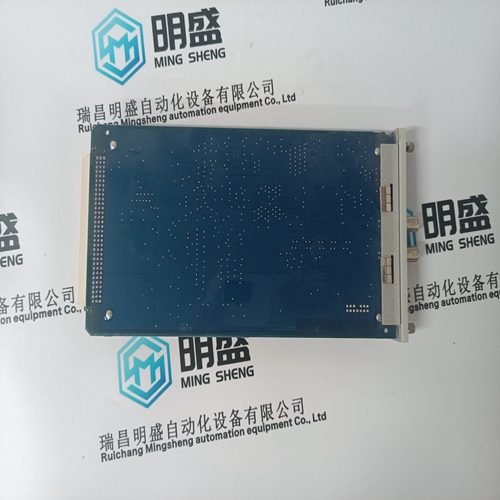

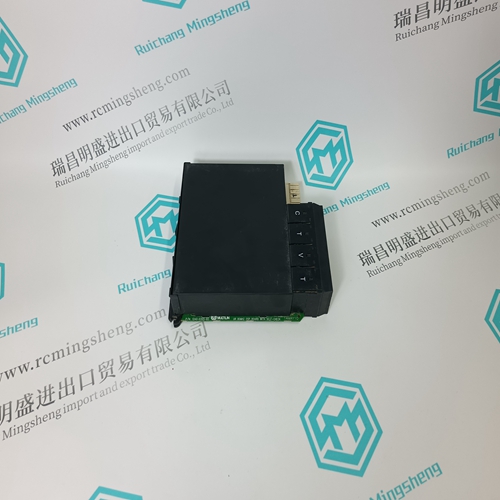

Home > Product > PLC programmable module > BENTLY 3500/25 184684-01 Monitor module

BENTLY 3500/25 184684-01 Monitor module

- Product ID: 3500/25 184684-01

- Brand: BENTLY

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:BENTLY3500/25 184684-01Monitor module

- Get the latest price:Click to consult

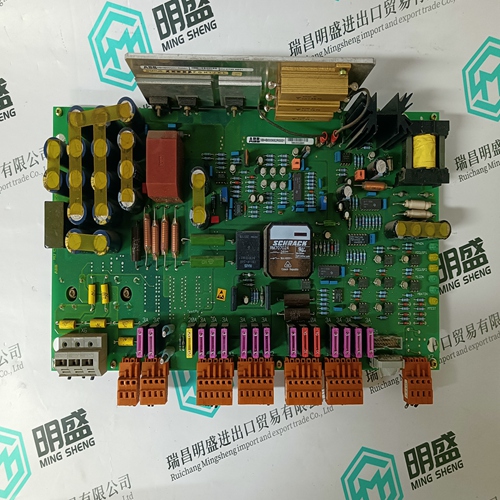

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

BENTLY 3500/25 184684-01 Monitor module

Favored in underground mining Nordberg C Series jaw crushers are very popular in underground mining applications. The possibility to dismantle the jaw crushers for transport makes them especially easy to use in underground installations. Moving the dismantled components into the tunnel requires less space in the tunnel and shaft and less heavy lifting. The crusher can be installed and commissioned in its final destination within a few days. These factors make the C Series the most favored jaw crushers for underground operations.

Metso rock breaker solutions are complete functional packages for rock breaking in the primary crushing stage. The breaker booms and hammers are engineered to meet the requirements set by rough primary crushing applications. These packages are optimized to work together and support Metso primary crushers, ensuring the best productivity of the whole primary crushing station.

Metso rock breaker solutions are complete functional packages optimized for primary crushing applications. Each component, breaker boom, rock breaker, hydraulic power unit and radio remote control, is optimized to work most efficiently with the other components. And each complete solution is optimized to work most efficiently with certain Metso crushers. Each component is engineered to meet the requirements set for the equipment used in rough primary crushing applications.

Significant improvement to plant capacity

Long-term plant production is significantly improved when the primary station is equipped with a rock breaker solution. Downtime due to build-ups and blockages can be easily cut to a minimum. This ensures a steady material flow through the primary station to the next process stages. The huge economic impact as a result of improved productivity means that the investment pay-back time is typically very short. The safest way to manage build-ups A rock breaker solution is clearly the safest way to manage blockages and build-ups and to clear the crusher cavity. The remote-controlled boom and hammer with the radio remote control, which is part of standard scope of delivery, means that the boom and hammer can be operated from a location that gives the operator unlimited visibility into the area where the rocks are moved or broken. Metso rock breaker solutions are also engineered safe and easy to maintain, with single-point lubrication of the boom joints as a standard feature.

Configured for your needs

NP Series impact crushers are the solution when output and productivity demands are increasingly stringent, from quarry to industrial applications and from mining to recycling. It's easy to build your own crusher configuration -- by adding options for your application -- like a full hydraulic breaker plate adjustment setting, a third breaker plate or different grades of steel and cast iron for the blow bars with the possibility for ceramic inserts. The Self Rotor Rotation system (SRR) is available across the NP range and is part of Metso's ongoing effort to innovate and find ways to enhance the quality, ease of use, and safety of its products. Metso IC ™ crusher automation controls the crusher operation and gives a perfect and complete overview of performance. Nordberg NP Series impact crushers feature a unique combination of heavy rotor design, materials selected for good wear resistance and crusher chamber design. This combination has proven revolutionary in improving capacity and product quality and in reducing operating and wear costs. NP Series impact crushers deliver unbeatable performances in primary, secondary, tertiary and recycling applications.