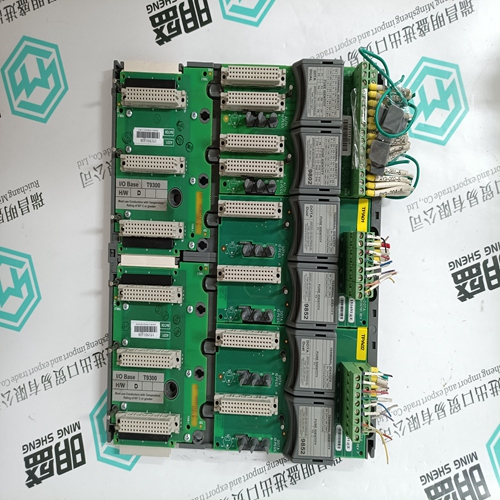

Home > Product > DCS control system > RH924UQ Field bus module

RH924UQ Field bus module

- Product ID: RH924UQ

- Brand: FOXBORO

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:RH924UQField bus module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

RH924UQ Field bus module

The A400 series was developed with the goal of offering a high performance camera to meet the most stringent requirements in terms of resolution, speed, and image quality. This goal was realized by using a sophisticated four megapixel sensor and a unique camera backend, a combination which provides brilliant image quality and the possibility of fast preprocessing. To ensure reliable, consistent quality, A400 variants are 100% quality checked and calibrated. All of this makes A400 cameras exceptionally flexible and reliable tools for many applications.

The A400 family sets a new standard of excellence with performance and image quality that rivals CCD cameras. The extraordinary image quality results from the use of advanced CMOS sensors and sophisticated electronic design. And three different image enhancement features can improve image quality even more: • Column shading correction to eliminate fixed pattern noise • DSNU shading correction to eliminate dark signal non-uniformity • PRNU shading correction to eliminate photo response non-uniformity The absence of blooming or smear represents another advantage over cameras with CCD sensors. Missing codes are not an issue for the A400 and the images are very homogeneous in this respect. The fast FPGA used in A400 cameras enables the option of onboard preprocessing and allows the implementation of individual algorithms adapted to customer requirements.

The AOI Feature, AOI Lists, and the AOI Editor

When the area of interest (AOI) feature on an A400 camera is used, only a designated portion of the image will be transmitted out of the camera. This reduces the amount of data transmitted by the camera and increases the maximum allowed frame rate. On A400 cameras, a set of individual AOIs can be defined in an AOI list. Each individual AOI can have different parameter settings such as AOI position, AOI dimensions, exposure time, and flash activation. The resulting sets of AOI parameters can be saved in the camera and executed internally. This means that the slow serial communication port is not needed to change from one set of AOI parameters to another and this allows higher frame rates during operation. The AOI editor software tool makes creating an AOI list simple. With this easy-to-use tool, each AOI in the list is created in a graphical way by using a captured image to position the AOI in the most interesting region and to adjust its size. The AOI list is automatically created, and it gives an overview of the positions, sizes, exposure times, delay times, and flash activation for each AOI in the list. The program highlights any incorrect settings and provides the information needed to make corrections.

Applications

A400 cameras are particularly useful in applications such as PCB inspection where the AOI feature is often used. Bare board inspection and flat panel display inspection are also applications where the A400‘s superior image quality and high speed are both required. Wafer inspection, bonding inspection, die placement, and packaging are all typical applications in the semiconductor market. Other applications include 3D measurement, document processing, and postal and document sorting

The most important benefits afforded by Camera Link are: • Accepted communication standard for vision technologies (camera frame grabber) • Simple and standardized cable concept • Particular suitability for high data rates • Standardized data protocol for several types of date transfer, for example single/dual tap, 8 bit, 10 bit, RGB, etc. • Serial communication to the camera via the frame grabber communication port