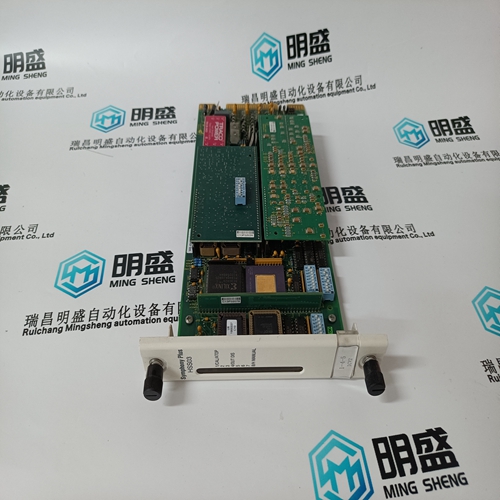

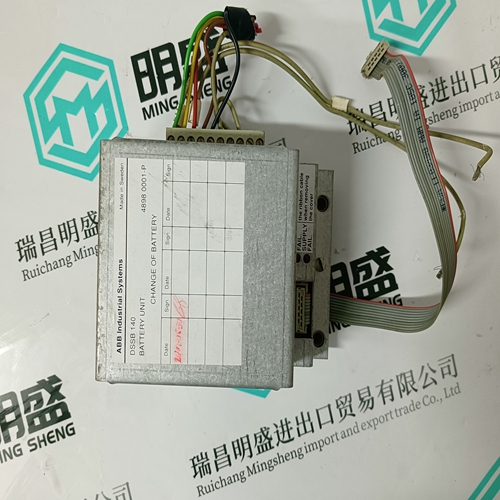

Home > Product > DCS control system > SPHSS03 signal processing card

SPHSS03 signal processing card

- Product ID: SPHSS03

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:SPHSS03signal processing card

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

SPHSS03 signal processing card

The ISOMAX range of directional control valves complies with ISO 15407-1 and VDMA 24563 for sizes 02 and 01 and ISO 5599-1 for sizes 1, 2 and 3. ISOMAX provides flows from 0.55 Cv to 4.15 Cv.

The ISOMAX range includes valves for pneumatic and electrical actuation with a wide choice of subbases and manifolds to suit different application needs.

All ISOMAX products use high-tech ceramic switching technology providing: Excellent reliability – Long life in excess of 100 million operations* – Operates with lubricated or non-lubricated air – Low sensitivity to air quality changes High performance – Slide valve concept allows high flow / size ratio and short response time due to short slide stroke and low friction Stable long lasting performances – Low friction switching: minimum wear of the valve member / seal assembly Valves fitted with switchable selector to give internal or external pilot supply Corrosion free and modern design Vacuum operation Dual pressure

The 369 Motor Management Relay

is a digital relay that provides protection and monitoring for three phase motors and their associated mechanical systems. A unique feature of the 369 is its ability to ‘learn’ individual motor parameters and to adapt itself to each application. Values such as motor inrush current, cooling rates and acceleration time may be used to improve the 369’s protective capabilities. The 369 offers optimum motor protection where other relays cannot, by using the FlexCurve™ custom overload curve, or one of the fifteen standard curves. The 369 has one RS232 front panel port and three RS485 rear ports. The Modbus RTU protocol is standard to all ports. Setpoints can be entered via the front keypad or by using the 369PC software and a computer. Status, actual values and troubleshooting information are also available via the front panel display or via communications. A simulation mode and pickup indicator allow testing and verification of correct operation without requiring a relay test set.

As an option

the 369 can individually monitor up to 12 RTDs. These can be from the stator, bearings, ambient or driven equipment. The type of RTD used is software selectable. Optionally available as an accessory is the remote RTD module which can be linked to the 369 via a fibre optic or RS485 connection. The optional metering package provides VT inputs for voltage and power elements. It also provides metering of V, kW, kvar, kVA, PF, Hz, and MWhrs. Three additional user configurable analog outputs are included with this option along with one analog output included as part of the base unit. The Back-Spin Detection (B) option enables the 369 to detect the flow reversal of a pump motor and enable timely and safe motor restarting. 369 options are available when ordering the relay or as upgrades to the relay in the field. Field upgrades are via an option enabling passcode available from GE Power Management, which is unique to each relay and option.