Home > Product > DCS control system > UFC760BE102 3BHB007030R0102 Thermocouple module

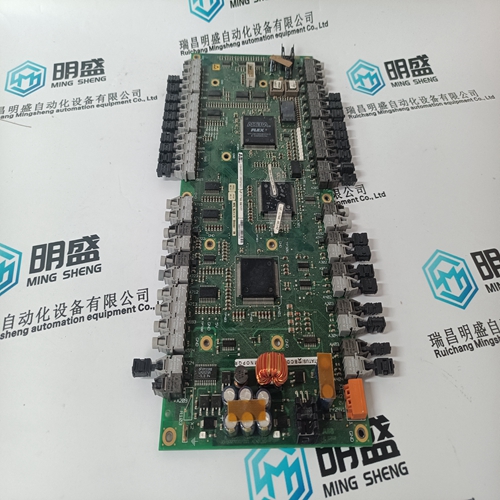

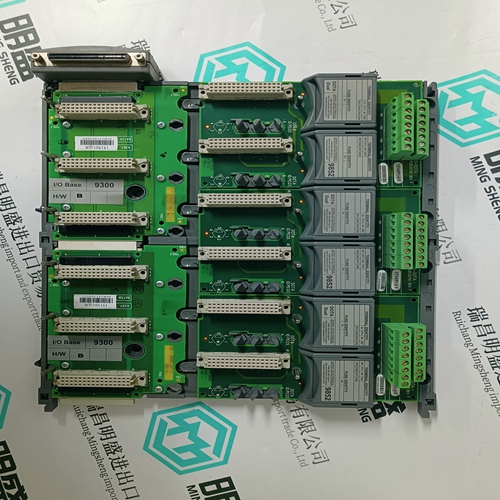

UFC760BE102 3BHB007030R0102 Thermocouple module

- Product ID: UFC760BE102 3BHB007030R0102

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:UFC760BE102 3BHB007030R0102Thermocouple module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

UFC760BE102 3BHB007030R0102 Thermocouple module

Materials marked with an "X" have been calculated using 100 000 h creep rupture strength values as given in EN material standards under consideration of the safety factor SFCR as indicated in Table F.2.5-2. The application of creep range within the p/t-ratings listed is limited up to and including 600 °C. This limit should be understood as a practical application limit and not as a restriction in use. If there is a need to extend this application limit to higher temperatures than 600 °C this can be done by individual calculations provided mean creep rupture strength values are given in EN material standards.p/t-ratings are given in Tables G.4.1-1 to G.4.1-12 for austenitic and austenitic-ferritic steels. They are calculated by using the strength values of steel forgings (see Table G.3.1-1) and are verified for flat steel products of the same group (see Table 9) up to and incl. 600 °C. Thickness related strength values for all thicknesses up to and including 150 mm have been considered. p/t-ratings are calculated by using the strength values of steel forgings and are verified for flat steel products of the same group.

Non-austenitic steels

G.2.1 General p/t-ratings are given in Tables G.2.1-1 to G.2.1-12 for non-austenitic steels. They are calculated by using the strength values of steel forgings (see Table G.1.1-1) and are verified for flat steel products of the same group (see Table 9) up to and including 600 °C. Thickness related strength values for all thicknesses up to and including 150 mm have been considered, except for material 1.4903 where v R ≤ 130 mm. p/t-ratings are calculated by using the strength values of steel forgings and are verified for flat steel products of the same group (see notes in Table G.1.1-1). 100 000 h creep rupture strength values are considered for materials marked with 'X' in Table G.1.1-1. Maximum allowable pressures at temperatures for which 100 000 h creep have been considered are indicated in italic letters in Tables G.2.1-1 to G.2.1-12. For flanges made from steel castings (type 21; material selection see Table 9) the p/t-ratings shall be the same as for the corresponding steel forgings respectively flat steel products (see Table 9). The wall thicknesses need to be verified (see provisions made in F.2.5). NOTE For nominal design stress values of steel castings it may be necessary to consider the provisions given in applicable component or equipment standards (e.g. EN 12516)

Flanges with fixed inner diameter

The Metric pipe standard has a fixed inside diameter (ID), which differs from the EN, DIN and ISO pipe standard that has a fixed outside diameter (OD). Mating dimensions of flanges and collars of the Metric system comply with the other mating dimensions of this standard.

This European Standard has been prepared under a mandate given to CEN by the European Commission to provide a means of conforming to Essential Requirements of the New Approach Directive 97/23/EC. Once this standard is cited in the Official Journal of the European Communities under that Directive and has been implemented as a national standard in at least one Member State, compliance with the clauses of this standard given in Table ZA.1 confers, within the limits of the scope of this standard, a presumption of conformity with the corresponding Essential Requirements of that Directive and associated EFTA regulations.

Permissible general membrane stresses for internal pressure, for predominantly static loads and for temperatures outside the creep range not exceed the smaller of the following values, according to the material used;