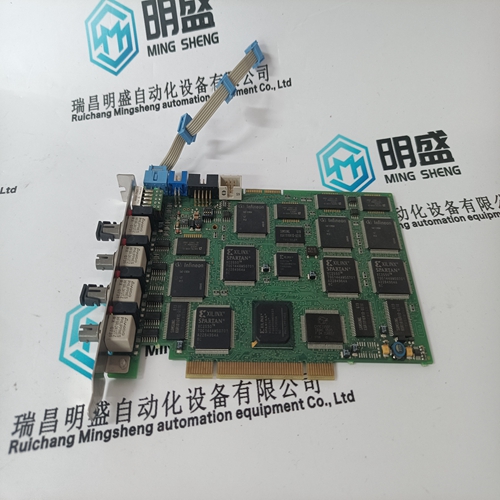

Home > Product > Robot control system > IBA ibaFOB-4i-S Relay output module

IBA ibaFOB-4i-S Relay output module

- Product ID: ibaFOB-4i-S

- Brand: IBA

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:IBAibaFOB-4i-SRelay output module

- Get the latest price:Click to consult

The main products

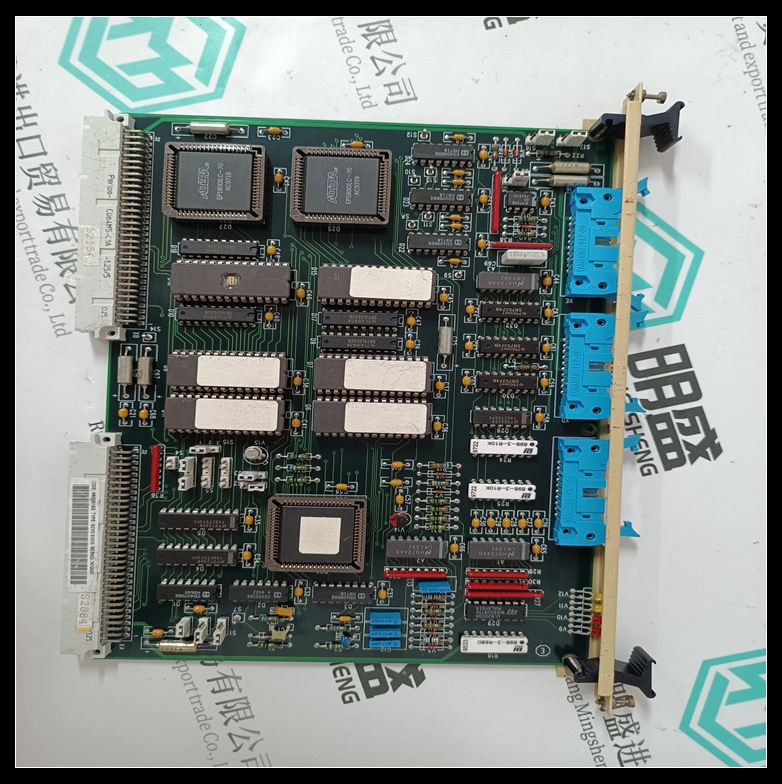

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

IBA ibaFOB-4i-S Relay output module

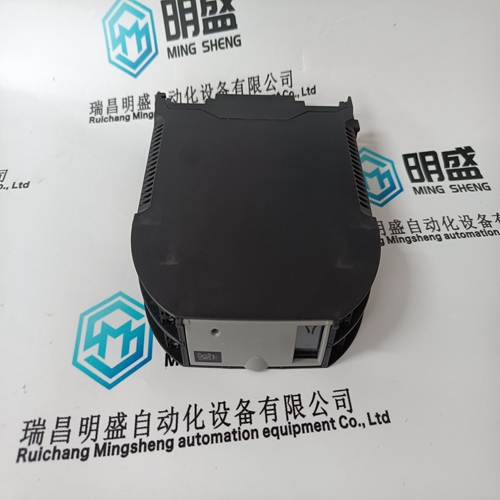

The drive modules comprise the following components: Power module, control unit, equipment bus cable and where relevant, a drive bus cable and option module. The permissible combinations of power module and control unit are saved in the engineering tables (refer to Chapter LEERER MERKER). Depending on the cooling method employed or the power module’s size, additional cooling components have to be ordered or be provided by the user. Depending on the application, the drive modules of the SIMODRIVE 611 converter system can function as feed, main spindle or induction motors, and comprise the power module, control unit, and drive bus cable components. Option modules can be added where applicable. A drive module is created by inserting the control unit into the power module, e.g. for feed or main spindle applications. The modular design of the drive modules allows a large number of applications to be implemented using only a small number of individual components.

Combinations that differ from the engineering information and instructions – where relevant, also in conjunction with third–party products, require a special, contractual agreement. We accept a warranty for our scope of supply up to the system interfaces that we have defined.

Power modules

A wide range of 1–axis or 2–axis power modules is available. These modules are graded according to the current ratings and can be supplied with three different cooling techniques. The range of power modules allows a seamless, modular and space–saving drive solution for: Small, compact machines (required feed torques and main spindle power ratings – e.g. 80 Nm at 500 RPM and 11 kW S1 at 1500 RPM) up to complex machining centers and automatic lathes – e.g. 115 Nm or 145 Nm at 2000 RPM and 100 kW S1 at 1500 RPM. The current–related data refers to the series–preset values. The output currents can be limited by the control unit being used. After the control unit has been inserted, the retaining screws of the control unit front panel must be tightened in order to establish a good electrical connection to the module housing. At higher clock cycle frequencies, ambient temperatures and installation altitudes above 1000 m above sea level, the modules must be derated. The appropriate pre–assembled cables are available to connect–up the motors. The ordering data is provided in Catalog NC 60, in the Motors Section. Shield terminal plates are available to meet EMC requirements when using shielded power cables. The equipment bus cable is included in the scope of supply of the power module. The drive bus cables must be ordered separately for the digital system.

Function of the power modules

The power module provides the required energy for the control boards and the connected motor. The power module is selected depending on the selected motor and the control board. 2.5.2 Connecting–up the power modules The power module is grounded through the PE connecting screws. The power module must be mounted on a grounded, low–resistance conductive mounting surface and must have a conductive connection to this mounting surface. Power is fed–in through the DC link busbars.The SIMODRIVE 611 control units use the power module to control the speed, torque and position of the attached motors. (Properties, for details refer to the module description in Chapter 4) 2.6.2 AC motors The following AC motors, for example, can be operated synchronously or asynchronously: 1FT/1FK servo motors 1PH/1PM induction motors 1FE1/2SP1 built–in spindle motors 1 FW torque motors 1 FN linear motors Third–party motors (when suitable!)