Home > Product > DCS control system > 1C31203G01 Analog channel CARDS

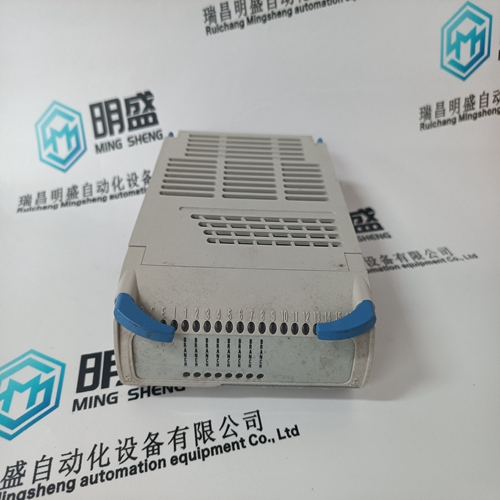

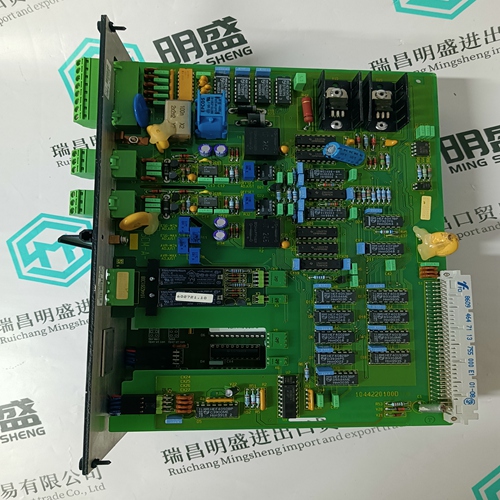

1C31203G01 Analog channel CARDS

- Product ID: 1C31203G01

- Brand: EMERSON

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:1C31203G01Analog channel CARDS

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

1C31203G01 Analog channel CARDS

The fan cable must be fed into the electrical cabinet using a PG gland to ensure that the degree of protection is maintained. The mounting panel must be sealed at the rear panel of the electrical cabinet so that a closed space or duct is created. Depending on how the cabinet is mounted (free–standing or installed in the machine), this must be cooled/ventilated via the roof/base assembly or the rear panel. Make sure that the air inlet is unobstructed. The distance to the side walls must be at least 50 mm. Fans must not draw in any air contaminated with cooling lubricant nor must they be sprayed with cooling lubricant, as this will considerably reduce their service life because of them sticking and cooling ducts can become clogged. For further information refer to the device–specific technical user documentation.To protect the motors, the specified motor protection circuit breakers should be connected downstream, which only switch a signal contact when the motor has an overload condition. If the motor is separated from the power module with the pulses enabled during operation, then there is the danger that the power module will destroy itself together with the control unit. Because of the harmonic oscillations in the current, set approx. 10% above the rated current!

Motors with holding brake

The holding brake mounted onto the motors is used to brake the motor when it is already at a standstill. In an emergency, it can also additionally reduce the braking travel. The holding brake is not an operational brake.The motor holding brakes should only be actuated at standstill. If the holding brake is operated during operation or while the motor is turning, this results in increased wear and shortens the lifetime of the holding brake. This is the reason that failure of the holding brake must already be taken into consideration when engineering the system. A hazard analysis must be performed.Danger Special attention and consideration must be given when holding brakes are used for suspended (hanging) loads (injury, crushing, possibility of death, machine damage) as this application represents a high potential hazard.

Motor encoder

The motors are equipped with various encoder systems to sense the rotor position and speed. Reference: refer to Appendix B in the relevant Configuration Manual of the motors The assignment of the SIMODRIVE units to the servo/main spindle motor types and encoder systems is shown in the Table 3-5. Depending on the requirements, various types of encoder are used and processed in the appropriate modules: sin/cos 1 Vpp or EnDat encoder SSI encoder (only SIMODRIVE 611 High Performance, High Standard, HLA/ ANA) Resolver (only SIMODRIVE 611 universal) TTL encoder (only SIMODRIVE 611 universal with induction motors) Induction motors can also be operated without encoders. The modules provide high encoder resolutions with internal pulse multiplication.If other encoder signals are used or in the case of TTL encoders, encoder signal monitoring can be triggered. In particular, the lower signal level for reference signals R+ and R– must be carefully observed.