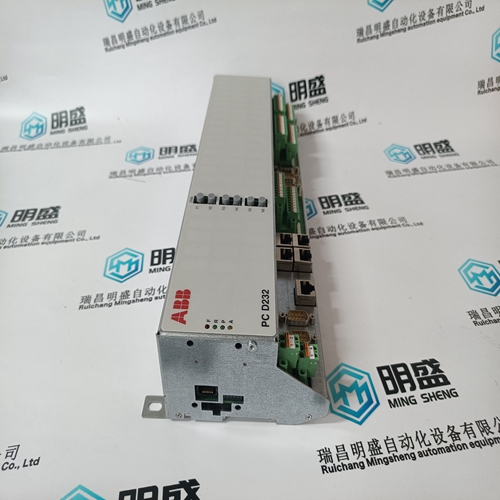

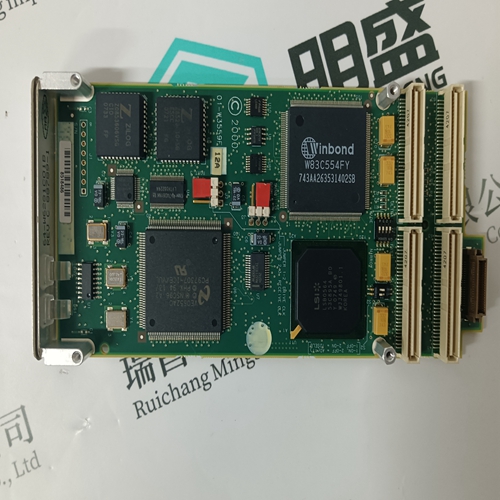

Home > Product > DCS control system > PCD232A 3BHE022293R0101 Control module

PCD232A 3BHE022293R0101 Control module

- Product ID: PCD232A 3BHE022293R0101

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PCD232A 3BHE022293R0101Control module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

PCD232A 3BHE022293R0101 Control module

When handling the operating unit or an interface for an external PG/PC (X471, X423 on the Profibus option) protective measures must be taken against electrostatic discharge: – Working with a grounded ESD wristband or – Wearing ESD shoes in connection with ESD flooring. Safe start inhibit The start inhibit is addressed via terminal 663 and is signaled back using a relay with positively–driven signaling contacts (AS1/AS2). Using the start inhibit, the energy feed from the drive to the motor is interrupted. When the ”safe start inhibit” function is correctly used, the signaling contacts AS1/AS2 must be included in the line contactor circuit or the EMERGENCY OFF circuit. Caution When using the ”safe start inhibit” function, it must be ensured that the velocity goes to zero. The ”SIMODRIVE 611 universal HRS” control board supports the ”Safe standstill” function. Detailed information about the ”safe standstill” function is provided in Chapter 8.5.

Serial interface (RS232/RS485) Option modules – Optional TERMINAL module, 8 digital inputs and 8 digital outputs for drive A – Optional PROFIBUS–DP module Expanded functions as of SW 5.1 The following expanded functionality is provided with a new control board for sin/cos 1Vpp encoders: – Higher internal resolution, interpolation factor 2048 (previously 128) – Pulse multiplication is possible (doubling) at the angular incremental encoder interface for absolute encoders – Pulse multiplication (doubling) and division (1:2, 1:4, 1:8) are possible at the angular incremental encoder interface, also for incremental encoders

Optional terminal module

An additional 8 digital inputs and outputs can be realized using this optional module. The functionality of these inputs/outputs can be freely parameterized. Note The input/output terminals of the optional TERMINAL module are – Before SW 4.1: permanently assigned to drive A or axis A – As of SW 4.1: can be freely assigned axes The optional TERMINAL module can be used as follows, dependent on the software release: – The following applies before SW 2.4: The module can only be used in the ”positioning” mode. – The following applies as of SW 2.4: The module can be used independently of the operating mode.

The hydraulics (HLA) module provides a means of controlling hydraulic axes directly from the SINUMERIK 840D system via the digital drive bus. The HLA module is a control unit belonging to the modular SIMODRIVE 611 converter system mounted in a 50 mm wide carrier module (universal empty housing). The gating and closed–loop control electronics for operating hydraulic drives are integrated in the HLA module. The control unit can also be used as an ANA control unit for analog axes. This double–axis board can be used in mixed operation (HLA/ANA). Hydraulic drives have the same significance as electric drives also when combined within an interpolating group.

The HLA module has the following features

Software and data The communications interface is compatible with SIMODRIVE 611 SRM(FD)/ARM(MSD) for supported services. Code and data structure is analogous to SIMODRIVE 611 SRM(FD)/ARM(MSD). The hydraulics software is stored as a separate program code in the control system. Hardware Integration into the SIMODRIVE 611 system is compatible with SIMODRIVE 611 digital SRM(FD)/ARM(MSD). Essentially, this involves the following interfaces: – Drive bus – Equipment bus – Power supply concept HLA control unit (2–axis) – Velocity pre–control, controller – Force control – Voltage output for actuators – Connection for two pressure sensors per axis – Control of hydraulic control valves Terminals and diagnostics – Control of a hydraulic shut–off valve – BERO input per axis – Module–specific enable signal – Test sockets (diagnostics)