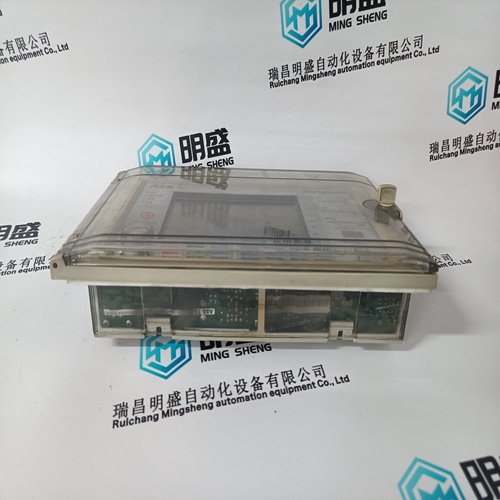

Home > Product > DCS control system > REF542PLUS 1VCR007346 Operation panel

REF542PLUS 1VCR007346 Operation panel

- Product ID: REF542PLUS 1VCR007346

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:REF542PLUS 1VCR007346Operation panel

- Get the latest price:Click to consult

The main products

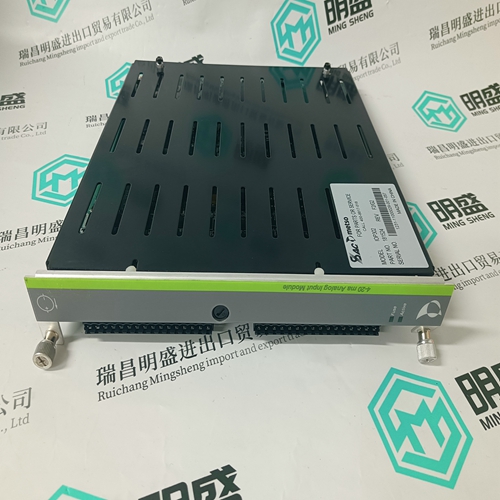

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

Products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on.

REF542PLUS 1VCR007346 Operation panel

The drive modules can be operated from both unregulated and regulated supply modules belonging to the SIMODRIVE 611 drive converter system. The engineering and power data of this Configuration Manual refer to operation with the regulated infeed/regenerative feedback modules. This data should be corrected, if required, when operated from unregulated infeed modules. Operating drive modules with PH and 1FE1 motors and induction motors from an unregulated infeed When operation is with an unregulated infeed (e.g. UI module or unregulated operated I/R module), a lower maximum motor output is available in the upper speed range than with the use of the infeed/regenerative feedback module. As a result of the low DC link voltage of 490 V (for a line supply infeed with 400 V 3–ph. – 10%) for the UI module or unregulated operated I/R module, the available continuous output is given by:VN motor should, for the particular motor, be taken from the appropriate documentation (refer to Appendix, References). As a result of the lower DC link voltage, it is possible that motor rated speeds will no longer be able to be reached, refer to Engineering the motors. In this case, the speed of the motors, and therefore the power, must be appropriately reduced.

Operating power modules from an unregulated infeed

5-138 © Siemens AG 2013 All Rights Reserved SIMODRIVE 611 Configuration Manual (PJU) – 06/2013 Edition Reader’s note Selecting the power rating for UI modules, refer to Chapter 6.7.4. For the 28 kW UI, the pulsed resistors must be separately ordered and externally mounted. For higher regenerative feedback powers, a separate braking resistor module must be provided or the regenerative power reduced by using longer braking times. Operating drive modules with 1FT6, 1FK and 1FN motors on uncontrolled infeeds As a result of the lower DC link voltage of 490 V1) for the UI module (600 V for the I/R module), under certain circumstances, the following restrictions must be expected: Reduction of the dynamic drive properties in the upper speed/velocity range Lower utilization of the rated motor speed/velocity if the requirement relating to overload is kept

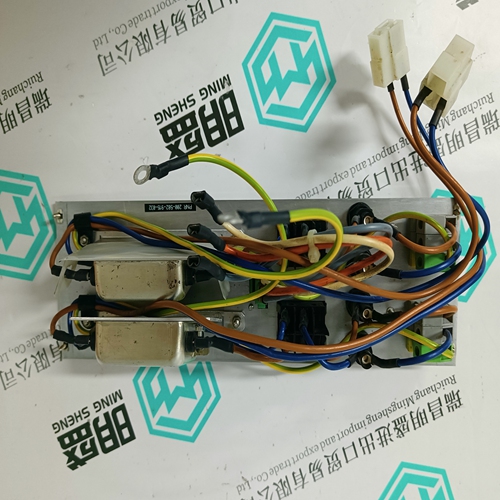

Infeed Modules 6.1 Description

The infeed modules are used to connect the drive group to the line supply. The infeed/regenerative feedback module (I/R module) and the module for the unregulated infeed (UI module) are used to input power into the DC link. Further, the I/R, UI, and the monitoring module also provide the electronics power supply for the connected modules. The infeed modules do not have any comprehensive overload protection. Such overload protection must be provided by the configuration and correct setting of the current values in the control boards. For the UI module, when the motor brakes, the drive energy injected into the DC link is converted into heat in the braking resistors and dissipated to the environment. These braking resistors are either integrated or mounted. When required, one or more additional pulsed resistor modules (PR modules) can be used within the limits specified when engineering the system. This module is used for the following applications: Machines with few or short braking cycles, low braking energy Drive groups with limited dynamic demands, in particular for the main spindle drive